Who Made That Frame?

Ever wonder where our frames come from? Did you know that part of our job is visiting foreign frame makers to bring you the best picture frames in the whole wide world?

The team is recently returned from our Grand Tour of European manufacturers. We suffered through two long weeks of amazing hospitality, friendship, food, and even more food. (Remember, we do this for YOU, our customers.)

In Spain, we saw bulls and stuffed ourselves silly with paella. In Italy, we strolled medieval lanes and sipped wine under the Tuscan sun. But most importantly, we toured nine picture frame manufacturing facilities; each varying in size and level of craftsmanship. In this blog we share with you an insider's look at the amount of craft that goes into making the frame on your wall.

It all starts out with the raw wood - lots and lots of raw wood. These giant stacks are all finger-joined pine grown in Scandinavia and responsibly forested.

Here’s one of those blocks of finger-joined pine going through a milling machine to be turned into a moulding profile. Special knives and blades are used to create each different profile shape. (Sorry for the shaking at the end!)

Here's the finished stack of the milled profile waiting to be painted and finished.

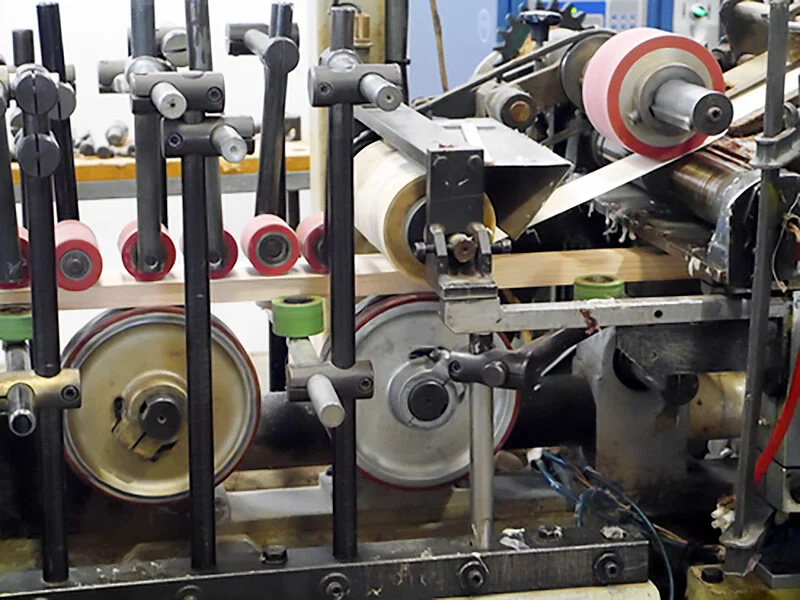

Each raw piece of wood goes through a machine fitted with lots of wheels specially adjusted to move the shape along the line. This one is getting a coat of glue before a very thin layer of maple wood veneer is applied to the face.

The wheels on the machines come in a variety of sizes and shapes to work with many different kinds of frame profiles. It can take a few hours to set up the machine between operations.

Lengths of moulding are stacked for drying and then moved around the factory between steps and machines on these large carts.

This is a fine example of a compo wheel. The ornate design will be stamped into a layer of wood composition as the wood rolls through the machine.

Some factories are fully automated but others still use some very old school techniques. These are jugs full of gesso and clay bole which will be applied by hand as a foundation before gold leafing. Looks like they’ve been using the same jugs since the Renaissance!

This artisan is applying silver leaf by hand. He will walk miles and miles each day traveling up and down the sticks of frame moulding.

No machinery in sight. Some of our richest and most special finishes are achieved through many coats of leaf, paint and lacquers - all done completely by hand. These guys have been making frames like this for generations.

Some of the frames we source on our adventures are only found stateside in our Chicago locations. Come in and see our exclusive selections. We love frames and we love offering you well-made and well-designed extraordinary options. That's no bull!